EPS cement sandwich wall panel machine EPS panel machine

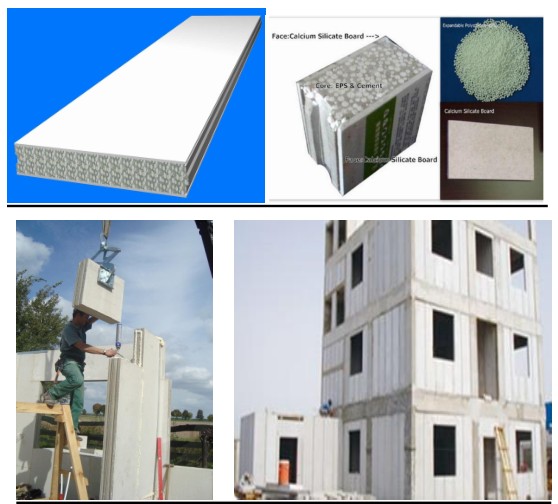

Brief introduction of EPS cement sandwich wall panel machine EPS panel machine ,Light weight thermal insulation simple eps cement sandwich wall panel production line:

(1). What's the raw materials for making the internal and external wall panel?

Main raw materials of EPS wall panel are: fly ash, slag, ceramic, portland cement and EPS foam particles, the production process is simple and low cost.

(2). The light weight wall board is suitable for modern building standard ,Light weight thermal insulation simple eps cement sandwich wall panel production line

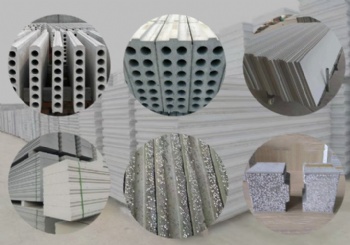

The overall world development trend of brick from clay to non-clay, from solid to hollow, from the small to large, from heavy to lightweight, from low intensity to high-strength, from high to low energy consumption. And the project is stressed to wall lightweight, high strength, thermal insulation, waste utilization, energy conservation and other functions.Therefore, the implementation of the project is imperative. The panel can meet the requirements of the modern building standard.

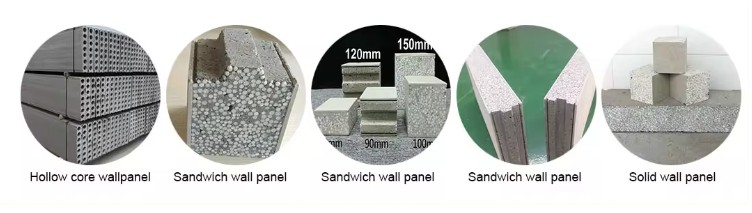

(3). Obvious Advantages of Industry Competition , EPS cement sandwich wall panel machine EPS panel machine:EPS new green wall board has five features ,Light weight thermal insulation simple eps cement sandwich wall panel production line:

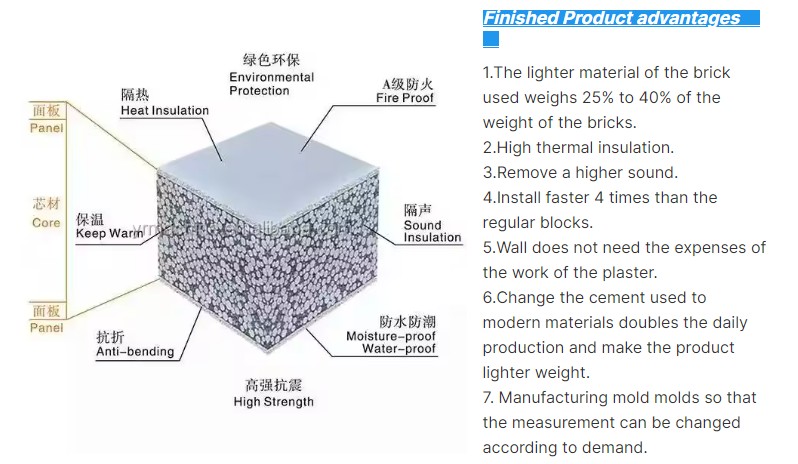

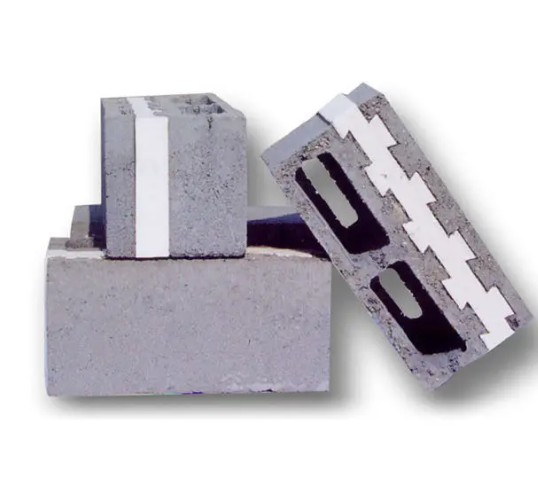

(A) Lightweight: The raw materials used are Lightweight aggregates, fly ash,etc, non-reinforced concrete, gravel and other heavy feedstock. So it has the characteristics of lightweight, which is only 1/16 weight of the brick and concrete structure.It can significantly reduce the vertical load of the building structure and reduces building weight and project cost.

(B)Insulation Resistance: As this new wall panel is core of EPS insulation materials, which insulation performance is extremely advantageous and meet the building energy efficiency design standards, and rank first among similar products.

(C) Permeability Resistance: The bibulous rate of this new wall panel is only 3.3%,which has reached the international advanced level in the same industry.

(D) Fireproof performance: this kind of wall panel is non-burning, and according to the testing, it is reasonable fireproof materials, for the 90mm thickness wall panel, the fireproof performance can be more 3 hours.

(E) Soundproofing: As new wall panel is using EPS as core, it has good sound insulation and air aspiration, which is more than 40 db sound insulation.

Light weight thermal insulation simple eps cement sandwich wall panel production line

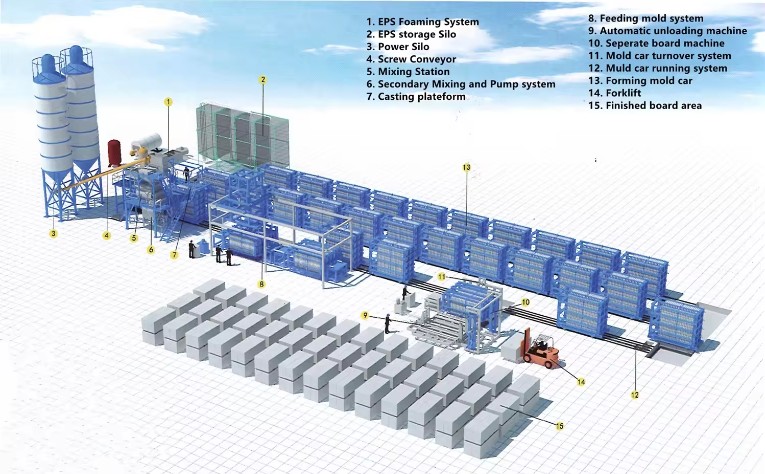

1.Main Feasture:

(1)The machine adopts PLC and touch screen control, automatic filling, electronic weighing, temperature control, material level control to realize automatic production.

(2) With the same machine, it can adjust the panel size and thickness. The thickness will be from 60 to 180mm.

(3) The closed constant pressure foamng barrel features of high heating efficiency and saves stem.

(4)High precise guiding pressure reducing valve controls the temperature and steam pressure of the closed barrel, ensuring the outcome pressure of the valve constant and the inner temperature controlled wihin ±1%, which keeps the foamed material equal and prevents the bead agglomerate because of the bad temperature control.

(5)With photoelectric or vibration sensor to control material level, ensuring density tolerance within ±3%.

(6)The machine is equipped with fluidized bed dryer, including drying, automatic sieving, depluming and material conveying to silos.

(7)Most components are of world-famous brands, with reliable performance, stable quality, long service life and low maintenance cost.

(8)The machine can realize the primary and second expansion.

1,Light weight---60mm thickness, about 55kg/m2

2,Excellent thermal conductivity---≤1.45 W/(m2·k)

3,Reputable sound insulation

4,Easy to cut and saw for any size and shape

5,High anti-impact capacity

6,High construction speed

7,Labor saving

8,Low investment

9,High output capacity: from 100,000m3 to 300,000m3 Annual output

Categories

Contact Us

- +86-531-69956097

- +86-531-69956097

- +8618253162396

- sales@biscgroup.com tim@biscgroup.com

- Skype

- +8618253162396

售前客服

售前客服